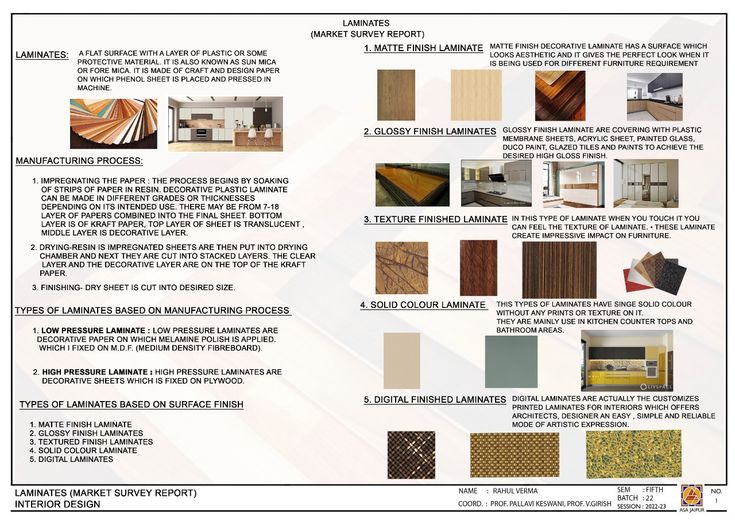

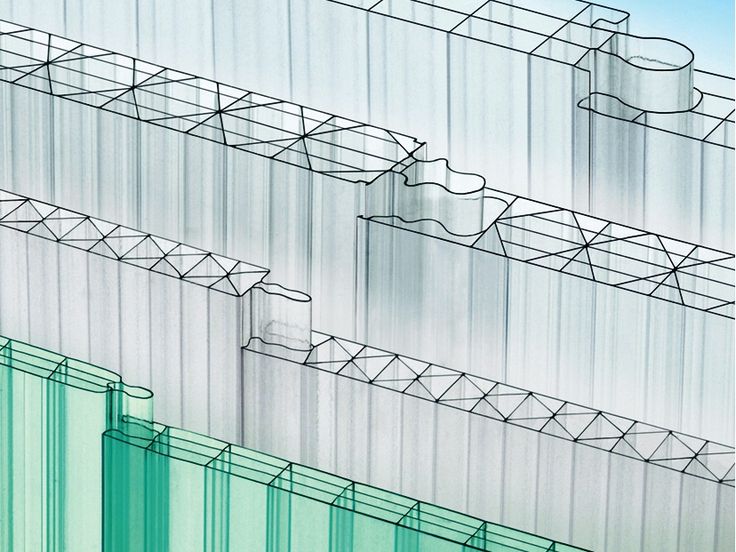

If you are unfamiliar with plastic laminate panels, you must first familiarize yourself with the term lamination. Lamination is a process of stacking multiple layers of any material together under high heat and pressure to form a compact, strong and durable material. Laminate panels can consist of 3-4 layers, but some good quality suppliers guarantee an additional 5 layersth Layer. Laminate is easy to install and the process is so easy you can do it yourself. However, if you are looking for an expert, you will be happy to pay the cheap labor cost.

Formation of plastic laminate panels

invention of plastic laminate panels happened by accident. To observe the effect, some brown paper sheets were dipped in melanin resin. In order to see the result, high temperatures and heat were still generated, which led to the production of plastic laminate panels. Plastic laminate sheets are very popular these days due to their wide range of uses, from electrical to household products. Plastic laminates can add vibrancy to your home with their versatile appeal. You can easily find wood, stone and marble prints on plastic laminate boards.

Use in the electrical industry

plastic laminate panels are often used in the electrical industry due to their high insulating properties. Laminate is often used for circuit boards and electrical wiring for sound and perfect insulation. Plastic laminating films are also frequently used in the automotive industry. You will find that car windshields are protected by laminated plastic films.

Use of plastic laminate panels for countertops

Now you can add stylish edging strips to smooth out sharp worktop edges. They come in a wide variety of colors, textures, and patterns. Edges can be processed in an enormous range of variations. To solve the problem, you can install laminated, square or curved laminate strips. Plastic laminating films come in a wide range of colors. Beige, black, blue, brown and cream are just a few of the diverse color palettes. You can choose your desired finish for the perfect finishing touch to your worktops. Fine, velvety texture, high definition, matte, quarry, and soft grain are the most common laminate finishes in the United States. Besides using laminate sheets as moldings, you can also spray paint them to enhance the appearance of countertops. However, one of the serious disadvantages of plastic laminate worktops is that when hot pans and dishes are placed on them, the smooth surface can become damaged over time. Sharp tools and cutting knives can easily scratch the smooth and delicate surface.